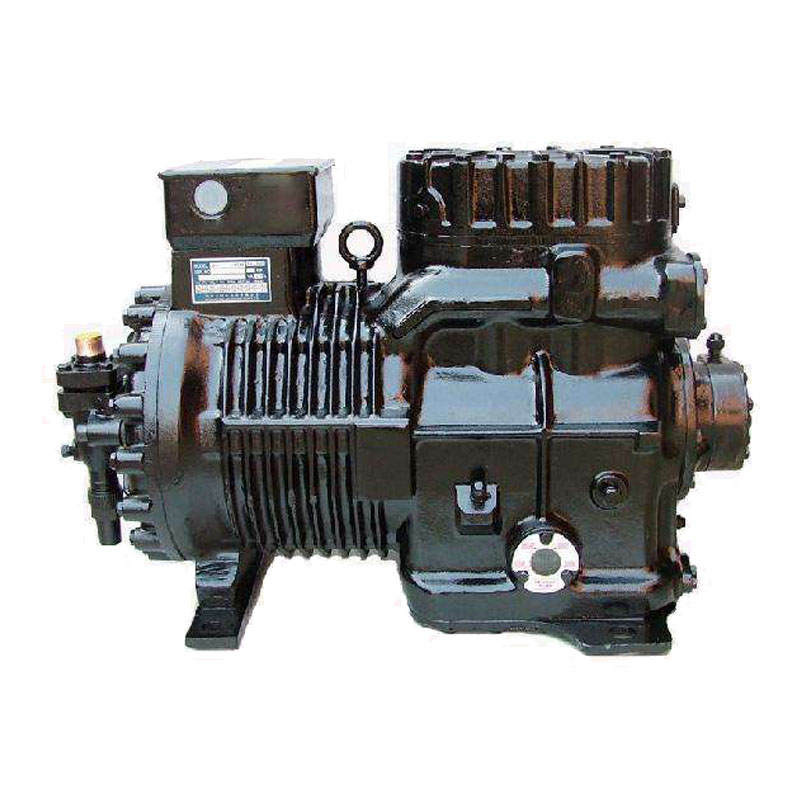

| Model | ZR61KC-TFD-522 |

| Horse Power (HP) | 5.1HP |

| Voltage | 380V-440V/3Ph/50HZ-60HZ |

| Refrigerant | R22 |

| Cooling Capacity(W) | 14550W |

| Cooling Capacity (Btu/h) | 49470 Btu/h |

| Displacement (cc/Rev) | 82.6 cc/Rev |

| Input power (W) | 4430W |

| Current(A) | 8.2A |

| COP(w/w) | 3.28w/w |

| EER(Btu/Wh) | 11.2Btu/Wh |

| Net weight(kg) | 36.1kg |

| Packing | Wooden Case |

Dirty blockage failures are caused by excess impurities in the refrigeration system. The main sources of impurities in the system are: dust and metal shavings during the manufacturing process of the refrigerator, the oxide layer on the inner wall surface falls off when the pipeline is welded, the inner and outer surfaces of each component are not cleaned during the processing, and the pipeline is not tightly sealed Dust enters In the tube, the refrigerating machine oil and refrigerant contain impurities, and the desiccant powder of poor quality in the drying filter. Most of these impurities and powders are removed by the drier when they flow through the drier. When there are many impurities in the drier, some fine dirt and impurities are brought into the capillary by the refrigerant with a higher flow rate, and in the curved section of the capillary The parts with larger resistance stay and accumulate, and the resistance becomes larger and larger, which makes it easier for impurities to stay until the capillary is blocked and the refrigeration system cannot circulate. In addition, the distance between the capillary tube and the filter screen in the filter drier is too close to cause dirty blockage failure; in addition, it is also easy to weld the capillary tube orifice when welding the capillary tube and the filter drier. After the refrigeration system is dirty and blocked, because the refrigerant cannot be circulated, the compressor runs continuously, the evaporator is not cold, the condenser is not hot, the compressor shell is not hot, and there is no airflow in the evaporator. If partially clogged, the evaporator will feel cool or icy, but not frosted. The outer surfaces of the filter drier and capillary were cold to the touch, frosted, or even hoarfrost. This is because when the refrigerant flows through the micro-blocked filter drier or capillary, throttling and depressurization will occur, so that the refrigerant flowing through the blockage will expand, vaporize, and absorb heat, resulting in condensation or condensation on the outer surface of the blockage. Frost. The difference between ice blockage and dirty blockage: after the ice blockage occurs for a period of time, the refrigeration can be resumed, forming a period of time-opening, blocking for a while, blocking and then clearing, and a periodical repetition of clearing and blocking. And after the dirty blockage occurs, it cannot be cooled. In addition to the dirty blockage of the capillary, if there are too many impurities in the system, the drying filter will gradually be blocked. Because the filter itself has a limited capacity to filter out the dirt and impurities, blockage will occur due to the continuous accumulation of impurities.

Dirty blockage failures are caused by excess impurities in the refrigeration system. The main sources of impurities in the system are: dust and metal shavings during the manufacturing process of the refrigerator, the oxide layer on the inner wall surface falls off when the pipeline is welded, the inner and outer surfaces of each component are not cleaned during the processing, and the pipeline is not tightly sealed Dust enters In the tube, the refrigerating machine oil and refrigerant contain impurities, and the desiccant powder of poor quality in the drying filter. Most of these impurities and powders are removed by the drier when they flow through the drier. When there are many impurities in the drier, some fine dirt and impurities are brought into the capillary by the refrigerant with a higher flow rate, and in the curved section of the capillary The parts with larger resistance stay and accumulate, and the resistance becomes larger and larger, which makes it easier for impurities to stay until the capillary is blocked and the refrigeration system cannot circulate. In addition, the distance between the capillary tube and the filter screen in the filter drier is too close to cause dirty blockage failure; in addition, it is also easy to weld the capillary tube orifice when welding the capillary tube and the filter drier. After the refrigeration system is dirty and blocked, because the refrigerant cannot be circulated, the compressor runs continuously, the evaporator is not cold, the condenser is not hot, the compressor shell is not hot, and there is no airflow in the evaporator. If partially clogged, the evaporator will feel cool or icy, but not frosted. The outer surfaces of the filter drier and capillary were cold to the touch, frosted, or even hoarfrost. This is because when the refrigerant flows through the micro-blocked filter drier or capillary, throttling and depressurization will occur, so that the refrigerant flowing through the blockage will expand, vaporize, and absorb heat, resulting in condensation or condensation on the outer surface of the blockage. Frost. The difference between ice blockage and dirty blockage: after the ice blockage occurs for a period of time, the refrigeration can be resumed, forming a period of time-opening, blocking for a while, blocking and then clearing, and a periodical repetition of clearing and blocking. And after the dirty blockage occurs, it cannot be cooled. In addition to the dirty blockage of the capillary, if there are too many impurities in the system, the drying filter will gradually be blocked. Because the filter itself has a limited capacity to filter out the dirt and impurities, blockage will occur due to the continuous accumulation of impurities.